Tips for Running a Mini brewery equipment

02/08/2022

2 vessel brewhouse what do we equipping when start a brewery.

01/12/2022

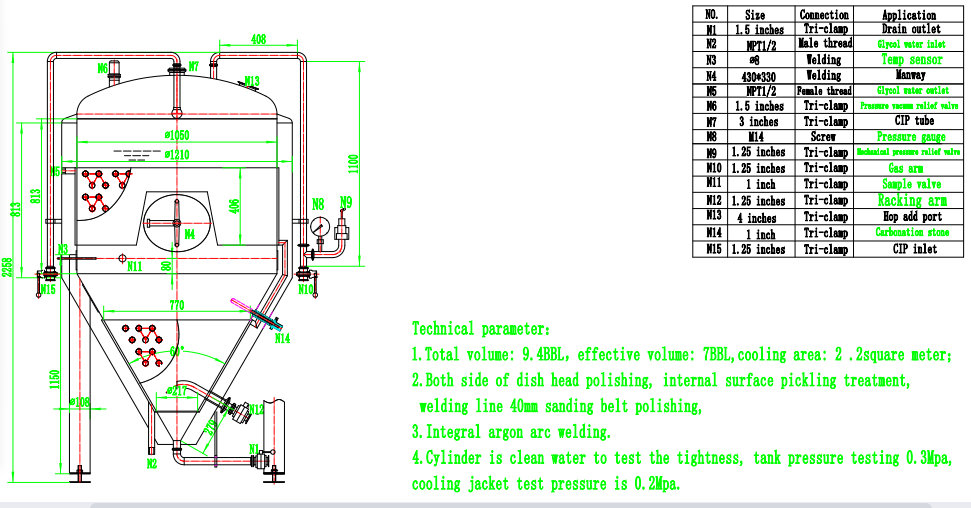

Stainless Steel Cooling Craft Beer Fermentation Tank Installed in France. The fermentation process is a key part of making beer. So, you plan on buying a commercial fermenter? But looking for some extra tips and advice before taking the plunge. it’s always better to go in prepared, before making an investment in brewery equipment.

I’ve been a salesman for 6 years and worked with numerous fermenters of different dimensions and design. Helping others with equipment sourcing. What I see time and again are clients overlook the importance of cooling fermentation tank. Plus understanding the importance of having the right vessels for their brewery project.

The fermentation process is a key part of making beer. It’s why I wanted to write this article. To show how to get the right Craft beer fermentation tank for your needs now and cover future growth. Let’s start with some of the basics?

What is a Fermenter?

We add yeast to the wort, which ferments the liquid turning sugar to alcohol. Carbon dioxide is produced during the fermentation process too, adding bubbles to the beer.

The yeast added to the wort also produces other metabolites such as esters, higher alcohols and acids which affect the flavor and aroma of the finished beer too. This all takes place inside a fermenter.

Having the right cooling fermentation tank to control the process is key to making good beer. There are a number of different styles of FV one can use in brewing.

In the UK, where real ale is popular, brewers often use open air fermenters. We are though going to look at cylindroconical FV’s. They are the most widely used Craft beer fermentation tank type in the brewing community, outside of the UK.

Buying A Commercial Fermenter Tips – Design

Cylindroconical Stainless steel beer fermentation tank’s have a conical bottom with a cylindrical top. In general, these tanks are 3 to 4 times taller than their width. They are fabricated from stainless steel, have adjustable footings (so it can be made level) plus the ability to “rack” beer.

The FV’s are insulated, having a “double wall”. Within this double wall there are internal cooling coils which allow glycol to run through them to regulate fermentation temperature.

We can thank a man named Leopold Nathan for the fermentation tanks design we use in breweries around the world today. He patented the cylindroconical fermenter in 1927. He claimed this design offered:

- Faster fermentation rates

- Lower costs to fabricate (less materials needed)

- Reduced operation costs (more energy efficient)

- Minimized floor space needed to house the wort

More Advantages To Using Cylindroconical Tanks

The fact Stainless steel beer fermentation tank is still produced like this, shows Mr. Nathan was right. The design of the cylindroconical tanks has many other advantages, which we’ve discovered in the intervening years. These include:

- Better mixing because of convection currents set up by rising gas bubbles

- Easier to control temperature of the fermentation

- Cleaning, sanitization and microbiological control is much easier in cylindroconical vessels compared to previous Craft beer fermentation tank designs.

- These tanks can be individually insulated.

- Automation of fermentation processes is much easier

- Collection of CO2 in primary fermentation and reuse is possible. As is spunding for better carbonation.

- Better yeast handling and recovery with collection from the bottom of the tank (cone). Cooling fermentation tank vessels make yeast handling more sanitary.

The modern cylindroconical fermenters usually have a 60 to 70° aperture, this angle allows yeast to flow towards the cone’s apex for easy recovery and re-pitching. In modern brewing fermenters are often “unitanks”, where both fermentation and maturation take place without having to move the beer between tanks.

Keeping the beer in the same tank for maturation is a huge advantage. It can help with beer quality, shorten processing times, offers space utilization and many other economies of production as listed above.

Buying A Commercial Fermenter- What Happens During Fermentation?

When beer ferments it’s an exothermic process. Meaning a reaction takes place which releases energy leading to an increase in temperature. As we said earlier temperature control during fermentation is important in the outcome of the finished beer.

In most breweries there are internal probes which measure the beer’s temperature constantly throughout the Stainless steel beer fermentation tank. If the fermentation goes above the temperature set by the brewer, its acknowledged by the control panel/PLC, and a signal is sent to open a solenoid valve.

Opening the solenoid valve allows glycol to flow through the internal coil cooling the fermentation down. When the beer temperature is within the set parameters the solenoid valve will close stopping the cooling.

Craft beer fermentation tank need to be well insulated, different types of material can be used between the double walls to help make it more energy efficient. When the beer is on chill after fermentation; it helps settle out the yeast and sediment. The insulation aids keeping the beer cold so, the glycol system doesn’t have to work too hard.

Now we’ve covered all we need to know about fermentation; we can take a closer look at the elements we need to consider when buying a commercial fermenter. Let’s start with manways.

Buying A Commercial Fermenter Tips – Manways and Dry Hop Ports

Manways are the “doors” used to access the fermenter. There are many types of manways to choose from. They can vary greatly in size and cost. In modern fermenters, the brewer doesn’t usually go inside to clean it (more on the subject later).

The rule of thumb for most seasoned brewers is; side manways for smaller fermenters, and top manways for bigger fermenters, say at 2,000 liters and above. However, it often comes down to personal preference.

One of the main concerns of having a top manway is accessing it. Ladders can be dangerous and if you need to dry hop through a top manway it can be particularly challenging.

You need to have safe access to the top manway; you can have a manual scissor lift or some purpose-built movable stairs for example. In big breweries they usually have a dedicated platform to access the top manways.

Clean In Place (CIP) – Buying A Commercial Fermenter.

As we said earlier most modern Stainless steel beer fermentation tank don’t require a brewer to go inside to clean them. They are cleaned by CIP. A tank has a CIP arm with an inlet and spray ball (see the picture below).

You put your cleaning solution inside the Craft beer fermentation tank, then you pump the liquid out of the drain outlet through the pump, and back into the tank via the CIP arm.

The power of the pump makes the CIP spray ball turn, with the cleaning liquid covering all surfaces inside the tank, removing any soiling or to sterilizing it. You usually run a CIP for 30 minutes depending on the chemical used and task needed.

Floor and Height Restrictions.

This is a quick section, mostly to say most manufacturers can tailor the dimensions of you a cooling fermentation tank vessel to suit the needs of a client. For example, if floor space is at a premium, a tank can be made “skinnier” to fit more volume on a smaller footprint.

Conversely you can make tanks “fatter”, They want to stack their 300 litre fermenters. The ceiling height is 3.5 meters so the plan is to make the stacked FV’s a little fatter so they can fit inside the building.

Fermentation tank were installed in Germany on 2016, because of the customer building size, we according to customer’s ceiling height to design fermenter.

Immediate and Future Needs – Buying A Commercial Fermenter

The prices of Stainless steel beer fermentation tank are not logarithmic, meaning a 2,000-litre vessel isn’t twice the price of a 1,000-litre vessel. With bigger tanks the work needed to fabricate them isn’t much more than smaller tanks. Mostly you’re paying for extra materials.

Depending on your needs and predicted future growth, it often to make sense to go bigger in the beginning. If you buy a 1,000-litre tank, you can only put 1,000 litres in it. However, if you buy a 2,000-litre tank you can put 1,000 litres of beer in it, when you start.

As you grow, you can then fill it to capacity, for example:

Say; you’re making an ale, which takes 21 days from brew day till it’s ready to be packaged. With a 1,000-litre tank you can make:

1,000 (litres) x 365 (days in a year) / 21 (days for one brew) = 17,300 litres per year

If you buy a 2,000-litre tank you can double your capacity (34,600 litres) for, say an extra US$1,500. It really is a no-brainer. Think about tank sizes and future needs; most breweries have a few different size cooling fermentation tankfor different beers in their range.

Buying A Commercial Fermenter Tips – Internal Pressures/Carbonation Stones.

Depending on the beer style made, you might need a tank to hold high pressures. Most fermentation tanks come pressure rated, with a maximum working pressure.

I’ve worked with tank which can hold a maximum of 15 PSI (pound per square inch). However, with most tanks now used for fermentation, spunding and maturation, I like my tanks to have a working pressure of 30 PSI.

It gives me the flexibility to quickly carbonate the tank, either by cranking up the pressure higher for natural CO2 absorption or through using of a carbonation stone. Most unitanks come with carbonation stones as standard, they are usually placed just above the cone and are handy to carbonate a beer quickly.

The higher the working pressure of the tank the quicker you can carbonate a beer. When I make wheat beers, I like to have a quick turnaround time to deliver fresh beer to the customers. Being able to spund the beer to 30 PSI really helps shorten the tank time of wheat beers.

Buying A Commercial Fermenter Tips – Conclusions

This article ended up being a lot longer than planned. However, it seemed necessary to cover all bases and fully evaluate all considerations when it comes to buying a Stainless steel beer fermentation tank.

Many people overlook the importance of a correctly designed FV when buying brewing equipment. People often put all their efforts into designing the brewhouse, however a lot of the “magic” happens in the fermenter.

Fermentation tank design should be properly evaluated with needs addressed if your brewing project is to be successful. As an example, please see a project I’m working on right now for a 300L system which needs to fit in a small space. We needed to “stack” the cooling fermentation tank.

One quick extra tip before I put this article to bed; most FV’s are made with chrome-nickel stainless steel. The surface of the tanks, should be as smooth as possible. Any crevices or scratches are areas for potential microbial contamination.

You need to get testimonials of suppliers before choosing one. Even better, visit the factory of some suppliers to see their work to get a feel for how they operate. Buying Craft beer fermentation tank is expensive, you need to get it right first time.