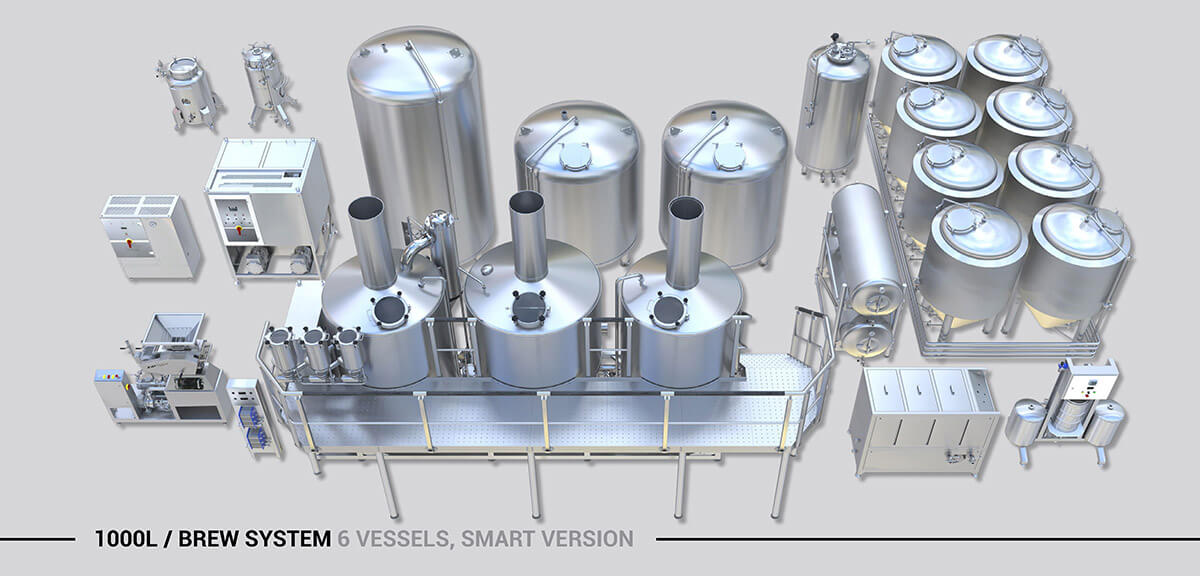

Factory Craft Beer Brewery Equipment

From the initial designs to the final installation.

We build 50L to 200HL beer brewing system.The heating mode can be selected according to the requirements of customers, including direct fire heating, electric heating and steam heating (diesel,gas or electric) .

We have a strict production system and a perfect after-sales system, for many beer lovers to achieve the dream of professional brewing beer, won the praise and recognition of customers.

- 304/316 food grade stainless steel

- Argon arc welding, internal and external polishing, no welding dead angle

- Sanding belt for welding protection of board surface

- Pickling and passivation inside the tank

- Complete cleaning system to avoid the production of bacteria

Beer Brewhouse Customized ( Two/three/four vessel ) brewhouse

Mash tank+Lauter tank+Kettle tank+Whirlpool tank

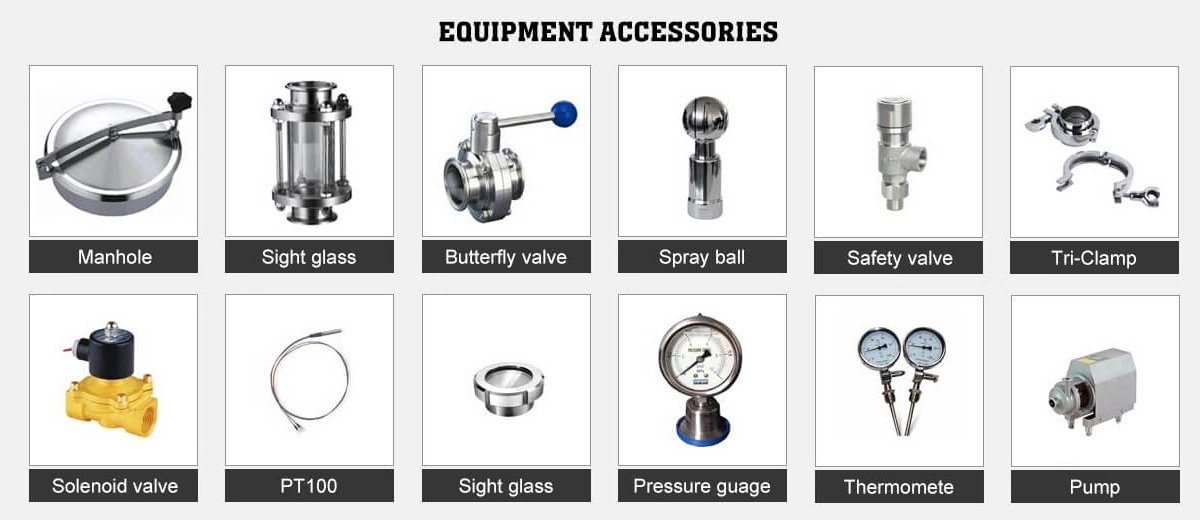

- Upper glass visible manhole

- CIP cleaning rotating washing spray ball

- Sanding belt for welding protection of board surface

- 4*Stainless steel legs

- Necessary pipe fittings valve fittings

Fermentation system

Conical fermentation tank

- Lower cone design: cone seal 60° angle (conducive to yeast discharge)

- Cooling method: Miller version jacket, reasonably designed cooling area

- Cleaning method: fixed all-round rotating cleaning ball,

- Temperature measurement method: PT100 platinum resistance

- Control system: automatic temperature control

- Manhole form: side oval manhole,

- Auxiliary equipment: hop addition port, cleaning valve, sewage valve, sampling valve, mechanical pressure regulating valve, breathing valve, ice water solenoid valve, etc.

Equipment Accessories

Frequently Asked Questions

1I want a complete brewing system, from grinding of malt to filtering of beer. Can you do it?

We will provide you with a one-stop turnkey solution. Regarding the requirements of beer equipment, we can help you achieve it, from the crushing of malt to the customers drinking your beer.

2What is the material of the equipment?

You can choose Stainless Steel SUS304/SUS316/red Copper,Stainless Steel SUS304 is the material we often use.

3What is the thickness of the tank?

They are double-layer tank,Polyurethane (PU) foam, Insulation thickness: 80mm.inner tank thickness 3mm, outer tank thickness 2mm.

4How to achieve temperature control?

The PLC touch screen control or intelligent instrument control could control the temperature by connecting with the PT 100 sensor. The brewing tanks with rock wool to keep warm, the fermenters and bright beer tank with PU as cooling jacket to keep cool.

5Is it easy to breed bacteria inside the tank?

Our tank is a tank with an internal and external polishing accuracy of 0.6μm, which will not breed bacteria, but also pay attention to the usual cleaning and sterilization.