Fermentation Tank

Beer Fermenters:

Fermentation tank is also an important part of brewing process, to insure the health of the fermentation process is the key of brewing good beer.

- Function: Use for keep wort fermentation or maturation.

- Component: It is consisted of Shadowless manhole, spunding valve, Aseptic valve, Pressure gauge, Rotate racking arm, Butterfly valve, Solenoid valve and etc.

- Material: Stainless steel 304 or 316,or red copper

- Capacity: effective volume is 50L-30000L, 1BBL-300BBL

- Cooling method: dimple plate or glycol cooling jacket around tank.

- Cooling media: glycol water or alcohol water.

- Design pressure is 0.3MPa; Working pressure is 0.15MPa.( Our standard design, MPa can be customized).

| Fermenter Series | Volume in US Gallon | Diameter | Height |

| 100L Fermenter | 26US Gallon | 620mm | 1600mm |

| 300L Fermenter | 79US Gallon | 960mm | 1900mm |

| 500L Fermenter | 132US Gallon | 1010mm | 2100mm |

| 800L Fermenter | 211US Gallon | 1060mm | 2550mm |

| 1000L Fermenter | 264US Gallon | 1210mm | 2550mm |

| 2000L Fermenter | 528US Gallon | 1560mm | 3100mm |

| 3000L Fermenter | 793US Gallon | 1760mm | 3500mm |

| 4000L Fermenter | 1057US Gallon | 1760mm | 4050mm |

| 5000L Fermenter | 1321US Gallon | 1760mm | 4540mm |

| 100HL Fermenter | 2642US Gallon | 2250mm | 5700mm |

| 150HL Fermenter | 3963US Gallon | 2250mm | 7550mm |

Note: 1hl=100liter; 1Gallon=3.7854liter; 1Barrel (BBL) =117Liter

Production Process

In order to improve the production quality and production efficiency of beer brewing equipment, our company has introduced many advanced automated production equipment, such as laser cutting machine, circumferential seam welding machine, longitudinal seam welding machine, circumferential seam polishing machine, longitudinal seam polishing machine, automatic pipe welding machine. , punching machine, bending machine, etc., greatly providing production efficiency and product quality

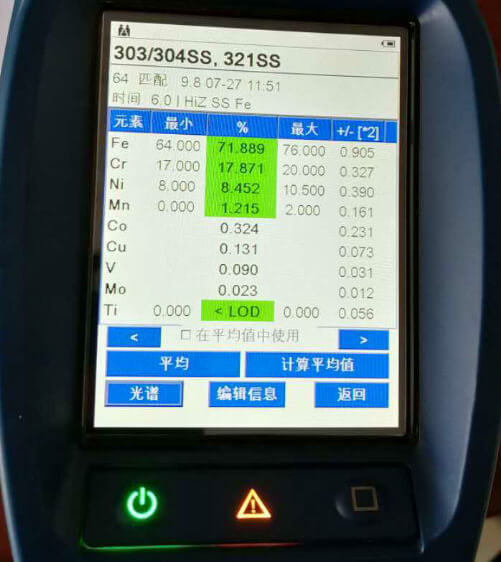

Quality Control

In order to ensure the quality of our products, our company has introduced spectrometers, thickness gauges and roughness testers. Through these testing equipments, we strictly control the quality of raw materials, production and processing details of our products, and provide customers with professional high quality products. Welcome to visit us and inspect the equipment in person.

Roughness measuring instrument

- It is used to detect the surface roughness of the tank body, ensuring that the tank body has no scratches, no gully and smooth.

- Not only the inside of tank surface will be inspected, the welding line out of tank also will be confirmed.

Stainless steel plate thickness gauge

Ability to quickly detect the thickness of SUS plate thickness, ensure that it is same with the customer's request. Provide the correct and good quality equipment to the buyers.

FAQs

1Why would I want a conical fermenter?

There are a number of excellent reasons to use conical fermenter for home brewing. They are very convenient, easy to use, and look great, too.

- First and foremost, a conical fermenter allows you to drop the trub and yeast out of the beer before and during fermentation by using the bottom outlet. This removes solids that contribute to off-flavors in your beer.

- Second, it allows you to capture your good yeast near the end of fermentation for re-use either immediately or later (you can store it in your refrigerator for a week or two).

- Third, you can use the same tank, without having to bother with a transfer, for primary and secondary fermentation.

- Lastly, it is very convenient for racking your beer directly into kegs using the side outlet. The bottom line is that a conical fermenter takes a lot of hassle out of home brewing.

2What are the tradeoffs of plastic versus stainless steel conical fermenters?

There are several key differences:

- Durability. Plastic is not as durable as stainless steel.

- Sanitary. Often brewers switch from large plastic tubs to glass fermenters due to concerns about the inevitable scratches that occur in plastic. If you purchase a plastic conical, consider that you will have to be extremely careful about causing bacteria-harboring scratches. Also, plastic fermenters will only have threaded fittings; there is no option for sanitary tri-clamp fittings like the kind made by Stout Tanks and Kettles.

- Light Exposure. Plastic conicals are somewhat translucent. We suggest wrapping a towel around it to prevent harmful UV light from reaching your beer. With stainless, you have no worries about that.

- Cost. Plastic conicals will almost always cost less – in the short term. However, because they are more susceptible to scratches, you could spend more in the long term because you will have to replace it sooner.

3What do I need in a brew fermenter?

Here are some critical items to consider before purchasing a brew fermenter:

- Is it easy to clean? Can you reach inside it?

- Can you easily inspect it for cleanliness?

- Can you see the welds inside the fermenter?

- Do you need to remove a lot of parts to clean it?

- Are there threaded parts with nooks and crannies that need to be dismantled to ensure cleanliness?

- Are the welds generally smooth, without pits?

- Can valves be disassembled for cleaning? (This does not apply to butterfly valves due to their sanitary design)

- Are there non-stainless metal parts, such as legs, that will rust with time and use?

- Is it made with 304 or 316 stainless steel?

- Does it include all necessary valves, and hose barbs, etc.?

4What do I do if my fermenter is clogged?

Here are some things you can try to help with clogged fermenters.

- Drain the trub 30 minutes or so after you dump your wort in (before you add yeast).

- Dump the yeast when fermentation slows down significantly.

- Dump a little yeast each day for several days in a row. Don't try to get it all out in one day. Once it gets very runny stop and close the valve. The more highly flocculent the yeast is the more it needs time to resettle so you can dump it again.

5Do I need a jacketed fermenter for beer brewing?

The short answer is no.

A jacketed fermenter has an extra "skin" on the outside of the tank that allows liquid to flow around the outside of the tank. By controlling the temperature of the liquid that flows around the outside of the tank, you control the temperature of your fermentation.

For those interested in building a commercial quality home brewery, a jacketed fermenter may be a better choice.

For home brewers, a conical fermenter does the trick just fine.

A jacketed fermenter has an extra "skin" on the outside of the tank that allows liquid to flow around the outside of the tank. By controlling the temperature of the liquid that flows around the outside of the tank, you control the temperature of your fermentation.

For those interested in building a commercial quality home brewery, a jacketed fermenter may be a better choice.

For home brewers, a conical fermenter does the trick just fine.