Turnkey brewery What Gets Missed Buying?

01/05/2022

How to Start a Brewing systems?

12/13/2021

Beer Brew Equipment quality i alwasys get asked. Chinese manufacturing suffers from pre-conceived notions of making poor quality equipment in many countries.

However, Chinese manufacturing suffers from pre-conceived notions of making poor quality equipment in many countries.

So today I want to dive into some of these pre-conceived notions; whether long held beliefs are still true today. Is it safe to buy Chinese beer brewing plant?

Lets us watch a Chinese Brewery machine video.

1. Chinese Beer Brewing Plant Use Poor Raw Materials

People will say China uses cheaper, inferior grade stainless steel than the West when making Brewery Machine for market.

The fact is cheaper doesn’t always mean inferior. In many manufacturing processes China can take advantage of economies of scale. As well as the fact they are many State-Owned Enterprises (SOE) making steel.

Let’s look at an example. If a Canadian steel manufacturer pays a worker $75,000 per year. Perhaps $35,000 of that is towards government taxes.

In China with a SOE you’re really paying your worker $40,000 per year, since the government would collect the tax anyway. Hence the true cost of human labor is cheaper.

Buying Good Chinese Beer Brew Equipment – The Indonesia Nickel Problem.

This is a simplistic explanation I know, but another example involves Indonesia. Indonesia has the largest reserves of nickel in the world. Nickel is crucial in the making of stainless steel. More than two-thirds of the world’s nickel is used to make stainless steel.

The Indonesian government announced in September 2019; it was banning the export of raw nickel ores from January 2020. However, Chinese steel firms (like Tsingshan) were protected from this ban as they operate their own stainless-steel plants inside Indonesia.

It affected the US, Canada and European steel manufactures badly.

Is Chinese stainless steel cheaper?

The short answer is yes. Is it of inferior quality? I will be honest; confirming there’s a full spectrum of stainless-steel of varying quality being made in China.

It’s worth noting, there are Chinese steel manufacturers making real innovations in their mills. Allowing them dominate not just the quantity market but produce quality steel as well.

For the standard stainless steel 304 and 316 (1.4404) used in Beer Brew Equipment manufacturing. China offers cheaper and good quality steel.

Always research the beer brewing plant manufactures you choose. Ask for references from overseas Brewery Machine who have already purchased from them. It’ll allow you to be confident in your choice of manufacturer.

2. The Electrical Components of Chinese Manufacturers Aren’t Allowed in the US and Canada

Yes, this is true in the US has the UL requirement and Canada has CSA standard. So typically, Chinese electrics will not be rated for use in these countries. However, it can vary from state to state in the US so check first.

A reputable Chinese manufacturer will be able to help you with this…

A Chinese Brewery Machine manufacturer that regularly supplies North American (or the country/region you’re based in) breweries know that they have to use local electronics for the project. Allowing them to meet local requirements.

The same can be said for the rest of the world. First check with your local authorities whether the use of Chinese electronics is permitted.

Again, speak with your potential beer brewing plant supplier. They may already have experience of installing in that country. If there’s an issue then work with the supplier to figure out a solution.

I’ve helped breweries in various countries now, from the US, Australia, Europe, South America to the UK source brewing equipment from China. There are fabricators who know the necessary procedures and checks.

3. Chinese Equipment Isn’t Designed Well – Establish Clear Expectations.

We are going to talk about Chinese quality control…

I hear people say “Chinese equipment manufacturers don’t understand brewing processes so the equipment supplied isn’t fit for brewing efficiently”. No, that’s on you…

When buying your brewing equipment, you have to be very clear on what you want. Some of the points to look out for are:

Agreed to specification list

So, what materials are to be used (e.g. do you want Chinese made solenoids or Western made ones?) If you’re clear from the start about what’s expected, both sides can be happy.

The type of brewery set-up you want

For example, do you want to have a hop filter to catch hop materials so they don’t clog the heat exchanger? Do you want to use a cold-water tank or two-stage heat exchanger?

Being clean and concise in the processes you require, and the set-up you want will save time, money and heartache. You’ll get supplied drawings of the equipment, manufacturers will be open with you.

The good Chinese equipment manufacturers want the project to be a success like you. It’s all about good communication and being specific in your needs.

Tank specifications

For example, to you want a racking arm on you unitanks or will a stand pipe suffice? Do you need bigger mash tun for high-gravity brewing? As above, be clear in your intentions for your Beer Brew Equipment.

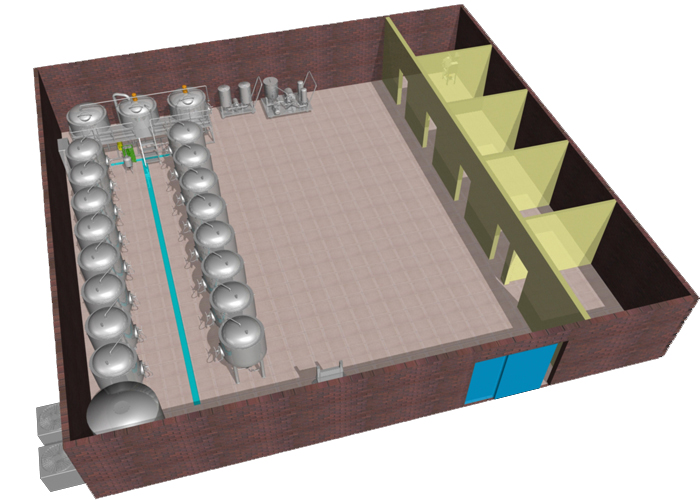

Brewery floor plan and utilities outlets

If you want an efficient brewing system, it makes sense to have it tailor-made to fit your building layout.

That’s why if possible, you should work with your equipment manufacturer, supplying as much information about the building as you can. It will lead to a better outcome and a more efficient brewery.

You’ll have a brewhouse and cellaring that best utilizes your space. Making sure the utility outlets (water, electricity and gas) are where they needed too.

Overall.

If you want an efficient brewing system that fulfils all your requirements; then you need to know exactly what you want your brewery to do.

Also having an agreed-to specification list; will protect you and lead to better quality control. However, it’s also critical for legal reasons, if there’s an issue with the supplier at a later date.

You need to be particular about your requirements and make sure you relay that to your supplier. You need to be clear about the quality of parts you want to use.

I go into this in more detail in my article “What Beer Brew Equipment do I Need to Start a Brewery?” if you’re looking to put your equipment list together.

4. How Do I Know I Will Get What I Asked For? – Check the Equipment.

When it comes to your brewing equipment you need to check it. Don’t just think about the final inspection (before shipping).

Before choosing your preferred manufacturer, it makes sense to visit several manufacturers on a visit to China. That way you can inspect their factory and see the quality of their work at source.

Get References

Before factory visits; it makes sense to reach out to suppliers asking for references. Preferably, from overseas breweries that’ve already bought equipment from them (locally to you if possible).

The cost of the equipment will still be cheaper than buying from Western Europe, even if you were to visit China. People often visit China for…

- Once for initial supplier visit

- During fabrication inspection

- Final inspection before delivery

If it’s possible, I would always recommend a visit during the fabrication process so that any issues can be sorted before it is too late.

5. Buying Good Chinese Brewing Equipment – Negotiations

When it comes to working with Chinese manufacturers; yes, price is a big pull, but it should not be the only point considered. It’s good to find the right balance between helping and arm-twisting to get the best price.

Yeah if I am Apple, I can act tough, but smaller business such a brewery needs to be more subtle. Here are some pointers:

Show the supplier that you know your industry

If you’re buying a brewery then you need to show the manufacturer you know what you want plus understand the brewing processes.

You need to demonstrate you know what you’re talking about. When it comes to the specifications and details of the brewery equipment required. This is a big deal to manufacturers.

Let Them Know That They Are Appreciated

I see it often people dealing with China and don’t show respect to Chinese companies. Yes, you’re bringing business to them but; they often have several projects already on-the-go.

They would like your business but not at all costs. When you have chosen your manufacturer take time to nurture that relationship. It’s all part of the important Chinese concept of guanxi (look it up or Google it).

Good communication though the fabrication process offering compliments when they do well. Though to promising to write a good testimonial for them. If you’re happy with the finished equipment will lead to better service.

Price Negotiations Are Expected.

In China even with brewing equipment there is certain wiggle room on price. It’s expected in China to negotiate somewhat.

There is a limit to how far you can push a price. However; you can have an ideal figure after the initial proposal has been offered by the manufacturer.

It could lead to the manufacturer lowering the price a bit or walking away. It is fine to say that you’re looking at other manufacturers and have several quotes.

Many manufacturers work on low margins anyway. So; if you are unrealistic in your negotiations and they agree. You can end up with inferior equipment (like the grade of stainless used).

That’s also why we recommend an inspection during the fabrication of the equipment. A brewery I know of; haggled really hard on price eventually getting delivered some extremely poor equipment.

When the brewery complained they were told “You got what you paid for!” There price should allow the manufacturer to make some profit. They have to pay wages too.

Buying Good Chinese Brewing Equipment – Conclusions

- Be specific in what you require

- Have good communication with the manufacturer

- Be respectful (guanxi)

- Have written agreements (agreed-to specification list) not just a contract

- Understand the manufacturer wants to make a profit too

- Have an agreed payment plan that suits both parties

- Make sure you do inspections at key stages