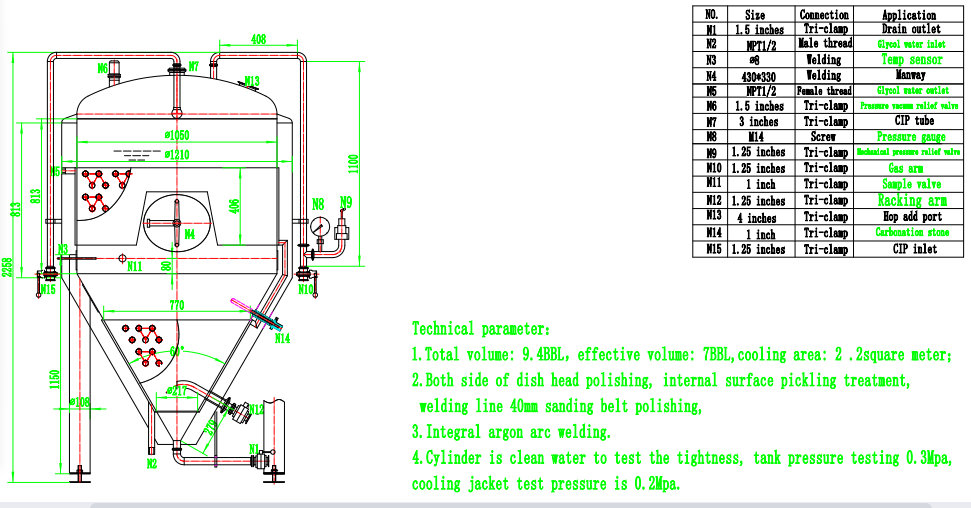

2000l glycol jacket stainless steel fermenter tank

08/19/2021

1000L craft beer brewery equipment in Greece

04/26/20217bbl Stainless steel beer conical fermentation tank

7bbl Stainless steel beer conical fermentation tank have a 217 gallon working volume with 25% head space for approximately 271.25 gallons total volume. More specifications as below:

- Interior Shell: SUS304 full welded; TH=3mm

- Exterior Shell:SUS304 full welded; TH=2mm

- 100% TIG welding with pure argon gas shield

- Interior Finish: Sanitary 2B finish, Pickled and Passivated

- Exterior Finish: Oil brushed finish

- Interior full polished to 0.2~0.4 μm without dead corner

- Insulated with high density Polyurethane foam; TH=80mm

- Glycol Jacket: Dimpled plate on cone and side

- Stringent tank leakage test by water and pressured gas

- Dished head and 160 degree cone bottom

- Sanitary side mounted manway with pressured door

- Tri-clamp connected CIP arm with 360° coverage spraying ball

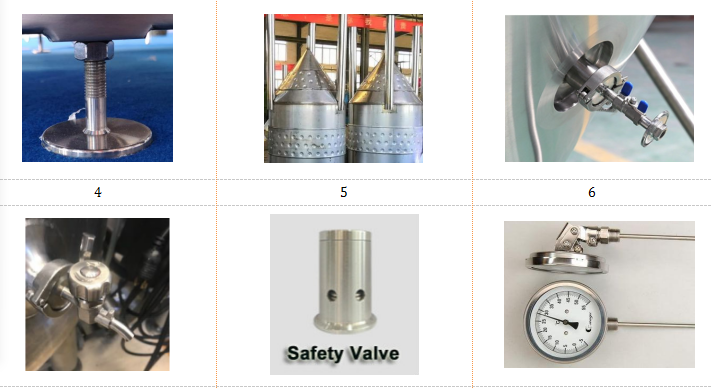

- Full sanitary metallic sealed mechanical pressure relief valve and hydraulic shock pressure gaugein gas arm

- Rotating racking arm and port on cone with butterfly valve

- Tri-clamp discharge arm with butterfly valve

- Thermowell for high accuracy temperature sensor

- Sampling valve and pressure vacuum relief valve equiped.

Stainless steel fermentation tank production standard

Fermentation tank raw material standard:

- Inner wall use 3mm thickness stainless steel 304.

- Outer wall use 2mm thickness stainless steel 304.

- Glycol cooling jacket use 2mm thickness stainless steel 304.

- Support legs made of one layer stainless steel 304 with 304 adjustable bolt .

- All fittings use stainless steel 304 as raw material.

Fermenter tank pressure device standard:

- Diaphragm pressure gauge, Psi / Mpa dual display pressure symbol.

- Mechanical pressure relief valve, rated working pressure 0.25Mpa, Adjustable rated working pressure.

- Pressure vacuum relief valve, rated working pressure 0.25Mpa.

Stainless steel fermentation tank overall sealing standard:

- Glycol cooling jacket testing pressure 0.2Mpa, duration 48 hours.

- Tank pressure testing 0.3Mpa, duration 72 hours.

- Pressure device testing 0.2Mpa, duration 48 hours.

Stainless steel beer conical fermentation tank purchasing FAQ

Q. Are there two separate glycol jackets in the cone and body, or one single glycol jacket?

A. Two separate honeycomb glycol jackets in the cone and body, jacket made of stainless steel 304, raw material thickness 2mm. Cone bottom 60 degrees.

Q. Other than the drop hop port, which is listed at a 4” TC port, are the rest of the ports 1.5” TC (other than glycol in/outs)?

A. Except for the four-inch dry hop port, the rest are 1.5-inch clamp connections.

Q. Are the glycol ports NPT? What is their size?

A. Glycol in/outs have NPT US standard screw, most of US customer use NPT type, and Stout/SSbrewtech also use NPT. NPT standard 1/4 , biggest diameter:0.536 inch, middle diameter: 0.5 inch, smallest diameter: 0.447 inch.

Q. Do they come with any sort of warranty? For example, if a tank leaks after arrival, what would be the remedy for an issue of that nature?

A.The Seller is responsible for freely maintaining the main equipment within Sixty months and electrical apparatus element within twelve months. And the quick-wear parts, such as the shaft gland and temperature sensor will be free warranty within twelve months. The seller could supply lifespan maintaining and technical service.

The above text will be included in the contract terms.

Simple explanation:

We will purchase transportation insurance for you before shipping. If there is a problem in the transportation of the goods, the insurance company will be responsible for the compensation of the loss.

If there is a problem with the accessories during the warranty period, we will send you new accessories for free by international express.

If the tank leaks after it arrives, please provide videos and photos. We usually have two processing methods for you to choose:

1. You keep the old tank and we will send you a new one.

2. We refund the full amount for the tank that has the problem.